Automation is on the forefront of industrial manufacturing for many years, though the increase of more info robotics has taken it to a complete new stage. Among these progress, arc welding robots have emerged for a groundbreaking Resolution for enterprises looking for efficiency, precision, and price-success.

Table of contents:

The Benefits of employing Arc Welding Robots in High-Precision producing

How Automation with Welding Robots enhances office Safety

Why Arc Welding Robots are perfect for significant-quantity manufacturing traces

These robots, like Individuals made by Genius, are redefining crucial elements of generation procedures. From boosting workplace protection to maximizing high-quantity output strains, arc welding robots have become a staple in industries globally, reworking producing eternally.

the advantages of making use of Arc Welding Robots in large-Precision production

One of the clearest advantages of arc welding robots is their Outstanding precision. irrespective of whether it’s welding elaborate metallic elements or sustaining uniformity across batches, automation ensures that each individual product fulfills the highest high-quality criteria. For industries like aerospace, automotive, and design, even the smallest inconsistencies in welding can lead to purposeful inefficiencies or safety threats. Genius, a leading Arc Welding Robot company, integrates Innovative systems like significant-rigidity robotic arms and laser monitoring, which offer unparalleled accuracy and consistency. With repeatability stages as superior as ± 0.03 mm, these robots can accomplish what guide welding merely simply cannot. Furthermore, this improves uniformity throughout output lines, appreciably lessening squander although guaranteeing customer gratification. By investing in significant-precision arc welding methods including those made available from Genius Robotics, corporations gain a aggressive edge in Assembly the requires of nowadays’s excellent-centric sector.

How Automation with Welding Robots enhances office basic safety

Workplace basic safety has usually been a concern in industrial production, specially when working with welding, a system that inherently requires large levels of heat, poisonous fumes, and electrical dangers. Arc welding robots dramatically enhance security by minimizing human exposure to those dangers. Outfitted with characteristics like entirely enclosed cables and anti-collision units, Genius Arc Welding Robots deliver an integrated security Remedy for production environments. jobs including positioning and welding that when required close human intervention can now be performed by robots, while operators oversee from a secure length. This not merely safeguards staff but additionally guarantees compliance with well being and security rules—a essential worry for all brands. A further notable element Genius incorporates is its sounds-tested robotic functions, which maintain degrees under 70 dB to ensure a quieter and safer Performing ambiance. By automating dangerous welding functions, manufacturers not merely lessen workplace accidents but will also improve worker allocation, enabling individuals to concentrate on considerably less risky, worth-added responsibilities.

Why Arc Welding Robots are perfect for substantial-Volume manufacturing strains

For organizations managing superior-volume production, speed and effectiveness are essential for sustaining profitability. Arc welding robots, Specially All those from trustworthy companies like Genius, thrive in such environments. Their ability to execute repetitive welding tasks with no fatigue ensures sustained productivity, a factor of utmost value in rapid-paced manufacturing options. Genius Robotics, certainly one of China’s foremost Arc Welding Robot brands, gives robots Geared up with Excellent payload ability and Innovative motion precision. These capabilities make it possible for their robots to accomplish at greatest effectiveness, even if built-in into complex generation systems. Furthermore, automation can help lower direct occasions by reducing bottlenecks within the welding approach. Outfitted with several Highly developed modes for various welding tactics—for example CO2, MIG, TIG, and in many cases laser welding—robots from Genius cater into a big selection of material-distinct necessities in industries like automotive and hefty equipment. Their remarkable technology not only improves output speed but will also ensures that just about every weld fulfills exacting benchmarks of top quality. The end result? elevated throughput, reduced production fees, and more quickly shipping to current market—all with out compromising on integrity.

Arc welding robots became indispensable while in the realm of industrial producing, offering unmatched precision, enhanced basic safety, and operational scalability. companies aiming to continue to be forward of the curve and streamline their output procedures can gain immensely from these automatic solutions. For companies searching for tailor-made welding remedies, Genius, a leading-tier Arc Welding robotic company, provides field-main types and technologies that cater to distinct organization needs. Whether you are Discovering techniques for prime-precision manufacturing, place of work security, or high-quantity generation, Genius Robotics delivers options that really jump out.

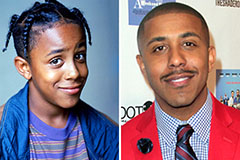

Marques Houston Then & Now!

Marques Houston Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now!